How On-Demand Hardware and Software Impacts Engineering Development

Every engineer running simulations has experienced the struggle of formulating a computation or simulation job and being unable to solve it due to hardware or software resource constraints. At Rescale, our goal is to eliminate these constraints and ultimately empower engineers to move up a level of abstraction toward simulation- and model-based design [mbd]. On-demand access to hardware and software resources changes how engineers can approach and solve the next generation of engineering challenges.

Most engineers have a basic level of access to internal high performance computing (HPC) clusters and simulation software–but access to on-demand resources opens up a broad set of new engineering problems that can be solved. Often, engineers are trained to solve their problems within these given constraints and do the best job they can with set timelines. This results in an under-representation for the real demand and opportunity if access to hardware and software were ubiquitous. Access to on-demand hardware and simulation software resources dramatically changes how engineers are able to utilize simulation in the product development process.

Lowering barriers to entry

At the most basic level, access to on-demand hardware and software resources dramatically lowers the barrier to entry for engineers to start running computational analyses. Significant upfront investments in hardware infrastructure or annual software licensing fees are not required with on-demand access as they have been in the past.

Higher fidelity models

Simulation models with higher fidelity designs can often give more accurate and higher confidence simulation results. With access to variable on-demand HPC resources, engineers can significantly increase the fidelity of simulation models without the need to invest in additional HPC hardware.

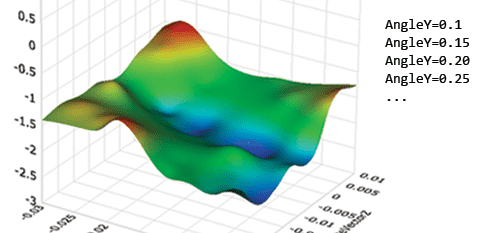

Broader design space exploration

Linearly scaling out simulations through parameter sweeps or designs of experiment (DOE) can be an extremely powerful way to better understand how specific elements of a model affect the outcome and provide critical engineering insights. Access to on-demand resources has a dramatic impact on these applications–commoditizing the incremental cost of a simulation and providing engineers and scientists the ability to run as many scenarios concurrently as they desire.

Algorithmic design development

Engineering models for complex systems have millions of parts and parameters which can be varied by engineers–often making a complete brute force search [bfs] of the entire design space impractical. Optimization techniques, statistical methods, machine learning algorithms, and other tools can be utilized to more intelligently explore these design spaces. A single function evaluation for these tools can involve the execution of a full simulation model that requires significant hardware and software resources. The ability to seamlessly execute these simulations is a critical enabler for simulation workflows that use this type of algorithmic approach.

Multidisciplinary analysis and co-simulation

Most complex products have several different engineering or scientific disciplines that influence the design. Simulation tools are often utilized for multiple components of the design process, providing the opportunity to combine the simulation tools (e.g. using functional mockup interfaces [fmi]) to understand how design changes affect each discipline independently while exploring correlations and interactions between them. When multiple simulation tools are connected together, the software and hardware requirements increase exponentially. These types of multi-discipline approaches are often used in conjunction with algorithmic exploration due to the highly complex interactions between parameters (e.g. multidisciplinary design optimization [mdo]). This often requires resource requirements beyond what has been traditionally accessible. Co-simulation is another example of this, but a more tightly integrated concurrent approach.

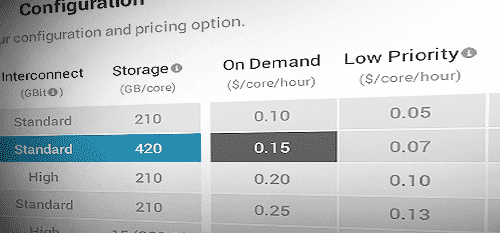

Engineering management and budgeting

Executives and engineering management often undergo a very difficult resource allocation and budgeting process in an attempt to predict the hardware and software requirements for a one- to three-year period while investing in capital expenditures for HPC clusters and annual software licenses accordingly. On-demand hardware and software resources allow for direct accounting and very granular budgeting approach. With the ability to calculate returns on investment (ROI) directly for simulations and understand the computing costs on a project basis, management can empower engineering teams to dynamically allocate resources as engineering and business needs change. This approach provides engineers the leverage to objectively assess the value of simulation tools and directly tie these investments to results.

Engineering and scientific simulation is becoming the critical tool that fuels the innovation pipeline for leading companies in industries and applications ranging from the development of new spacecraft and unmanned aerial vehicles (UAVs) in aerospace to revolutionary new drug discovery techniques in life sciences to advanced electronic design automation (EDA) for the next generation of semiconductor devices. Access to on-demand resources for hardware and software provides engineers the tools to move up a level of abstraction in the development process. This dramatically improves the ability to handle large complex models and utilize simulation driven development as a key asset for innovation and breakthrough technologies.

[mbd]: https://en.wikipedia.org/wiki/Model-based_design

[bfs]: https://en.wikipedia.org/wiki/Brute-force_search

[fmi]: https://en.wikipedia.org/wiki/Functional_Mock-up_Interface

[mdo]: https://en.wikipedia.org/wiki/Multidisciplinary_design_optimization