David and Goliath: The Agility of Rescale Big Compute Enables RF Antenna Design Startup to Disrupt Market: Customer Interview with Optisys

Optisys is a small, radiofrequency (RF) antenna design company based in Utah. Using revolutionary 3D metal printing technology and 50+ years of experience in RF engineering, Optisys specializes in 3D printing custom RF antenna solutions for military and commercial applications. The company’s focused, highly-qualified team competes with established incumbent RF suppliers. Keep reading our interview with Optisys cofounder and CTO Mike Hollenbeck to hear how Optisys uses Rescale’s cloud platform to find strength in its size—by strategically using the cloud to tap into the world’s largest HPC infrastructure network while preserving the agility to move quickly and keep costs low.

Rescale: What should we know about Optisys? Describe your company and your technology.

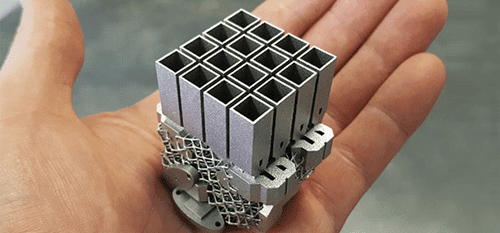

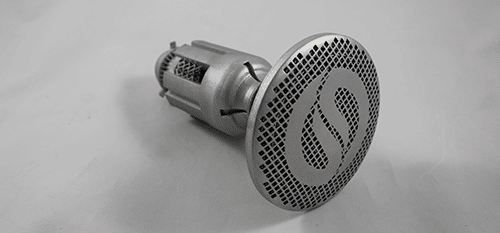

Mike Hollenbeck: We design, print, and test metal 3D-printed antennas and RF components. RF antenna design is a very unique field in that we only care about what’s on the inside of the object. To design a quality product in this industry, we have to be involved in the full cycle—from the RF design, to the mechanical design, to the design for additive manufacturing. Optisys fills a void in the 3D printing industry. Unlike a lot of contract manufacturers that primarily focus on printing parts with specific external features, we’re designing RF components with high-quality internal features using this brand new fabrication process that allows us to generate designs and geometries that you couldn’t even dream of five years ago.

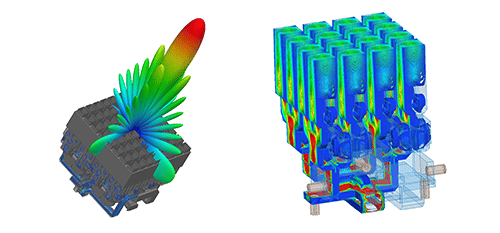

At Optisys we focus on RF and antenna components, but we also love to integrate several parts into a single 3D print to improve size, weight, performance, and cost of the system. 3D printing is a new way to design, such that we’re not limited by the old fabrication processes. We can make systems that are far superior in performance, and we can redesign from scratch rather than just printing parts from old designs. We can integrate multiple different pieces in a very space-efficient way and take part counts from the hundreds down to single-digits. We print highly-integrated parts with the minimum amount of material required by physics for RF performance, structural performance, thermal dissipation, or mechanical interfaces. There’s no way to get lighter than this. Through simulation, Rescale and ANSYS allow us to verify that that’s the case.

The environmental and mechanical environment that these parts have to endure is sometimes extreme. We perform simulations to verify that we are using sufficient material for strength, vibration, and thermal, but not too much that we’re over-engineering as traditional fabrication processes do. In addition to aluminum, we print other metals as well. We can do various forms of steel, titanium, cobalt-chrome, and some others.

– Mike Hollenbeck, CTO & Co-founder, Optisys

Rescale: What’s your role in the organization?

Mike Hollenbeck: I’m the Chief Technology Officer and the Lead RF Designer. I create air volumes that capture RF energy and then I pass those designs to our mechanical engineer, who wraps metal around them and puts in all the support structures needed to build these parts.

Rescale: How do you use simulation at Optisys?

Mike Hollenbeck: The RF design world is very simulation-heavy right now. The fundamental equations that govern RF design are impossible to solve manually in a reasonable timeframe, and you really need simulation tools to design complex structures in the industry today. At Optisys we use the best in industry tools, ANSYS, for both our electromagnetics design and our mechanical designs. We use simulation for all the passive RF components in the system and all the structural components that integrate with the RF components.

“We didn’t want to reinvent the wheel”

Rescale: Can you tell us about your IT solution before you started using Rescale? What were the pain points that led you to consider cloud computing?

Mike Hollenbeck: We all come from the aerospace and defense world where the IT is walled off in a company intranet that is maintained by an IT department. Everything takes time including software upgrades. At Optisys, our philosophy is that we want to be able to do our simulations on-demand from anywhere. We don’t all need to be in one building or connected to one intranet. Before Rescale, we had to set up the electromagnetics licenses and the mechanical package licenses on local workstations such that only one person was able to use them at a time at a given computer. It was a non-ideal solution since we are located in diverse regions of the US (the headquarters is in Utah, but I live in New York). We weren’t happy with it.

But we didn’t want to set up a local intranet and server to check out licenses, like companies have traditionally done. We have a core competency of designing and fabricating 3D-printed antennas, and we don’t want to set up an IT department, an intranet, and local systems that are outside of our core competency. That’s really the pain point. We felt like we had to reinvent the wheel to set up our IT. Then we stumbled into cloud computing on Rescale in a very fortuitous way.

– Mike Hollenbeck, CTO & Co-founder, Optisys

Another pain point is that we didn’t want to buy new high-performance computers for our simulation every two to three years. It’s costly to purchase and maintain hardware—and then the hardware becomes antiquated and doesn’t scale well with problem size. You have to buy for your largest problem. Then for the majority of your problems you’re wasting that extra hardware because you’re not fully utilizing it. With Rescale, we don’t need hardware in-house. We don’t have to buy a system to handle our highest workload and our hardest problem types. We can scale our hardware solution depending on the work that we’re performing on any given week, which is really an amazing option.

Rescale: How did you stumble upon Rescale?

Mike Hollenbeck: We work with Starburst, which is a startup accelerator platform. They mentioned Rescale, and it sounded like exactly the IT solution we needed to solve our IT problems. That interaction pointed us towards Rescale, and we researched it and just dived right in.

Rescale: Did you consider any other cloud HPC providers or just Rescale?

Mike Hollenbeck: We did a brief search, and Rescale was the best out there—absolutely the best. One of the big selling points was that Rescale supports ITAR simulations, which is a huge thing in our industry. A lot of our customers have ITAR data. Having that extra layer of security and the ability to handle ITAR simulations is a huge benefit.

“Rescale has allowed me to tackle larger problem sizes”

Rescale: Can you tell us about how you use Rescale? Let’s start with software and licensing.

Mike Hollenbeck: Primarily we use Rescale for ANSYS HFSS and ANSYS Mechanical simulations. We have our licenses hosted on Rescale, and so I’m able to set up my model on my ANSYS program locally, verify that it’s working properly, set up an optimization, and then send it to the Rescale platform to run the optimization. One of the great things is that it frees up my local machine so I can start working on the next model immediately, and so I can get other things done while my optimization is running on the Rescale platform. Before, if I had two simulations running on two computers, both computers were completely tied up and it was very hard to do anything else. Now that I’m able to push all the hard computing stuff to Rescale, not only does it run faster, but it also it frees up my local machine to get other work done, which gives me a huge boost in productivity.

Rescale: What types of simulations do you run on Rescale?

Mike Hollenbeck: I predominantly run optimizations on Rescale. I simulate relatively small models that take one to two minutes to run, all the way up to larger models that take 15 to 30 minutes to run. I like to scale up the resources to complete within those simulation times because my optimizations require dozens or hundreds of simulations to run over a set of parameters to find an optimal solution. What’s great is I can monitor my optimizations in real-time to see if my goals are being reached.

– Mike Hollenbeck, CTO & Co-founder, Optisys

Rescale: Can you give an example of a simulation that you ran on Rescale and how Rescale impacted the design process or your results?

Mike Hollenbeck: Recently I had a model that was way too large to run on my computer. It exceeded the memory, so every time it either killed my computer or took hours to run one simulation. I was able to make it run in 10 minutes on the Rescale platform, such that I could find an optimal geometry.

In general, Rescale has allowed me to tackle larger problem sizes. Instead of limiting myself to small-to-medium problems that I can run on my local computers, I can now scale up to larger problems and optimize them quickly, which is key for what I’m doing. It’s been an enabling technology for me and has significantly improved my efficiency and speed in simulation.

Rescale: What else has Rescale enabled you to do that you couldn’t do before?

Mike Hollenbeck: Rescale is allowing me to offload all of that hard computing so that I can work on other things that require computing resources, like running a company. Being able to scale up on the Rescale platform without impacting my local hardware has been a huge benefit. Another great thing is that as the company grows we’ll be able to add people without purchasing individual node-locked licenses and expensive hardware just for them. The ability for them to immediately start simulating is huge. And we don’t have to be in the same office—we can do this from various locations depending on travel or living situations.

Achieving operational efficiency: faster time to market, no CAPEX, focus on core competencies

Rescale: How has Rescale helped you operate better? Let’s start with simulation throughput.

Mike Hollenbeck: Rescale has helped me parallelize multiple projects at once. It’s been so beneficial and such a huge improvement to my efficiency that we’re actually going to be adding more licenses of the ANSYS electromagnetics package, because now I have the bandwidth and resources to simulate more. It has enabled us to handle more simulations, which allows us to take on more design work and get more done in a quick amount of time.

Rescale: Has it affected your time to market?

Mike Hollenbeck: Oh absolutely, absolutely. Rescale easily gives us a 3-4x improvement in simulation speed for the vast majority of problems, and it’s significantly more for large problems that I couldn’t efficiently handle before. In terms of time to market, it’s allowing us to take RF design cycles from months down to weeks.

Rescale: Does Rescale give you good ROI or cost savings?

Mike Hollenbeck: It is quite good. When you look at it from the hardware perspective, we would be spending $10,000 to $20,000 per computer to run one license of ANSYS. That would have to be refreshed every two to five years in order to stay current on hardware performance improvements. Now, we don’t need to invest in hardware for a local intranet. We also don’t have to get any kind of local license hosting software. It’s saving us capital in multiple different areas.

Rescale: Has your revenue been impacted?

Mike Hollenbeck: We expect a significant impact in terms of our ability to generate revenue. We’ll be able to take on more programs, and we’ll be able to get them done efficiently, quickly and on time.

Rescale: Has Rescale impacted your staffing or your staffing plans?

Mike Hollenbeck: It’s actually allowed us to focus more on staffing for engineering positions, rather than having to staff for the things that aren’t in our core domain of expertise. That is hugely beneficial because we don’t have to divert funds away from the things that we do well in an effort to reinvent the things that we don’t do well.

“Organizational agility enables us to compete with large companies”

Rescale: Has using the Rescale platform impacted your organizational agility?

– Mike Hollenbeck, CTO & Co-founder, Optisys

Mike Hollenbeck: Absolutely. It’s allowed me to travel frequently and work from New York, Salt Lake, or conferences or customer sites. It enables me to keep a continuous stream of simulation going so that we can meet our contractual obligations for our designs, and to innovate without any slowdown due to a hardware bottleneck. As we add more people, we will be able to get them running on our software and hardware from day one. Rescale has been huge for the organization, absolutely huge.

Rescale: Can you talk a little bit to how that organizational agility—the ability to scale your simulations on unlimited, uninterrupted computing power while on a busy travel schedule—allows a company like Optisys to compete against the major companies with large resources?

Mike Hollenbeck: The organizational agility we achieve with Rescale is a critical enabler that allows us to compete with larger incumbent companies with large resources. Hardware is expensive and simulation tools are expensive. For a startup company it’s really hard to juggle your finances if you have to pay for full licenses, the hardware, and put an IT program in place. Rescale has allowed us to bypass all of that headache and cost for our hardware solution. We don’t have to amortize any upfront hardware expenses over a number of years. We don’t have to purchase hardware for our highest workloads and our hardest problems.

We pay only for the simulation we use, and we can scale our hardware capabilities to the problems that we have that day. Without Rescale, it was harder to compete with big companies because we were limited to solving certain types of problems. Rescale makes us significantly more competitive than big companies because it gives us capabilities in excess of what they have, combined with the agility of a small company, so we can make decisions a lot faster. We can do simulations a lot faster, and we can get our products to market a lot faster now.

Rescale: Could you talk a little bit about the ease or difficulty of moving to the platform and how hard it was to get spun up? Was there a learning curve, or was it a fairly turnkey implementation?

Mike Hollenbeck: Spinning up on the Rescale platform was easier than I expected by orders of magnitude. First off, you guys have been amazing to work with. You’ve been incredibly helpful and extremely responsive. You’ve bent over backwards to make sure that the solutions that I’m trying to run can be run and that I’m getting the right outputs. On top of that, the basic ScaleX workflow worked excellently for exactly what I needed to do. It worked from the start. It was awesome. There are just a few pre-filled batch commands that you have to use. It was a very, very small learning curve to use the Rescale platform because it’s all flow-driven and intuitive—you just need to upload your files, put in the file name, get the licensing information in, and then it just works. I’ve been beyond impressed with how easy it’s been to use Rescale successfully from day one.

Rescale: In addition to using our compute resources, what other Rescale services do you use or plan to use?

Mike Hollenbeck: We are very excited to use license hosting. A lot of companies spend a lot of time, effort, and money on license management systems to track license usage, but Rescale’s license hosting saved us a lot of pain and suffering and makes us a lot more efficient. It also fits with our core philosophy that we should be able to work from anywhere, and license hosting allows us to do absolutely that.

“Rescale has been the best thing to happen to us”

Rescale: How do you see Optisys using Rescale in the future?

Mike Hollenbeck: Rescale is and will remain the hardware platform for Optisys as we grow. It makes total sense. There’s no reason why we would develop an IT team, a full suite of hardware, and our own license management software internally. Why would we spend all that money when the Rescale platform allows us to be very agile, have all of this functionality, and you guys are experts and provide amazing customer service?

Rescale: Do you want to make any other comments?

Mike Hollenbeck: Overall, we’ve been more than pleased with Rescale. It’s been the best thing to happen to us. Between Rescale and the ANSYS Startup Program and Amazon Activate, it’s been the best thing to happen to our company. It allows us to compete in this new field of 3D printing, which is expanding exponentially and enabling unprecedented capabilities.