自動車業界向けのHPC

ソリューション

世界のトップ自動車メーカー10社のうち7社がRescaleを採用

世界のトップタイヤメーカー6社のうち4社がRescaleを採用

自動車の流体力学の最適化から、燃焼や電動化の効率解析、衝突安全シミュレーションまで、自動車エンジニアはRescaleのプラットフォーム上で幅広いコンピュータ支援エンジニアリング(CAE)シミュレーションを実行し、新しいモデルの自動車をより迅速に製造しています。

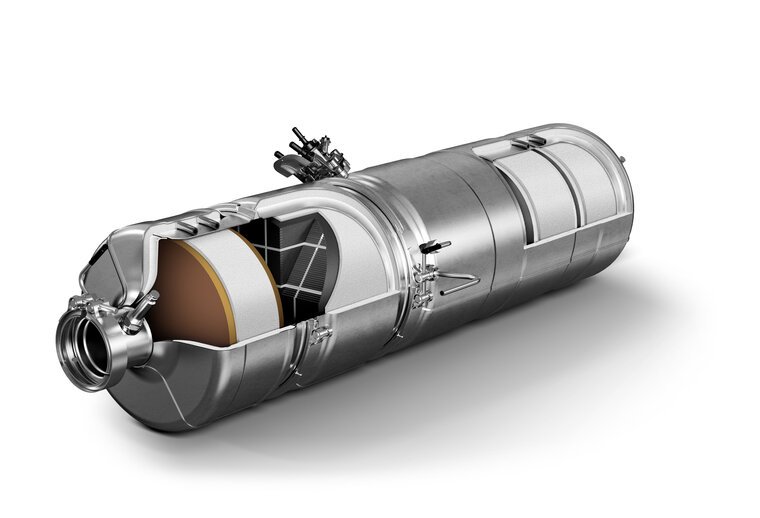

お客様事例: Dinex A/S

Dinex A/Sは、トラック、バス、およびオフロード車両のための排気および放出システムの設計と製造を行う世界的企業です。Dinexは、中国のトラックメーカーの排気処理システムを設計するためにRescale ScaleXを採用しました。Rescaleを利用することでDinexは以下を実現しています。

シミュレーションの実行時間の短縮

シミュレーションのシミュレーション時間を4倍に高速化

スケーラビリティ

シミュレーションのボトルネックの解消により、シミュレーションエンジニアの生産性が向上

効率化

- プロジェクトの処理能力の向上と、新たなプロジェクト追加による収益の増加

- 市場投入までの時間を25%削減、プロジェクトの時間を18ヶ月から13.5ヶ月に短縮

CFD、FEA、その他の自動車シミュレーションの機会

複雑な自動車サプライチェーンを構成する自動車メーカー、OEM、その他のエンジニアリング会社は、コンピューター技術を使用して、より安全で効率的な車両を製造しています。 消費者向けの乗用車やトラック、企業向け車両には、それぞれ独自の要件があります。

何よりもまず、乗員、歩行者、インフラへの損傷を防ぐために、すべての車両が特定の安全基準を満たさなければなりません。 現地の要件やさまざまなシナリオに確実に準拠するために、自動車エンジニアは、有限要素解析 (FEA) などのマルチフィジックス モデルを含む広範な衝突シミュレーションを使用して、自動車のさまざまな部分と乗員が衝撃に対してどのように反応するかを理解しています。

次に、各車両クラスには、たとえばレーシング車両の空力など、性能に対する独自の要件があります。 空気力学やエンジンの燃焼効率などのその他のシナリオでは、エンジニアは数値流体力学 (CFD) シミュレーションを使用して車両のパフォーマンスを最適化することがよくあります。 FEA シミュレーションと CFD シミュレーションは両方とも、高度に結合されたワークロードです。つまり、高度なモデルの複雑さと忠実度の要件があり、そのため計算リソースの需要が高くなります。 Rescale は、各アプリケーションまたはワークロードに基づいて最適なアーキテクチャの構成を自動化し、解決時間を短縮し、忠実度の高いメッシュを分析し、クラウドの柔軟性を利用して多くのシミュレーションを並行して実行することもできます。