Boundary Layer Technologies Case Study

Disrupting the Cargo Industry

Boundary Layer Technologies is a category-defining company. They design small hydrofoil cargo ships posed to disrupt the transportation industry. Currently, the only options for intercontinental shipping are air and traditional cargo ships. Air is quick but very expensive; whereas, ships are cheaper but significantly slower, up to ten times slower. There is an industry need for transportation in the middle ground. Hydrofoil ships can travel twice as fast as traditional cargo ships at a far lower cost than air travel. “A hydrofoil cargo ship uses an airplane wing under the water that lifts the hull up allowing it to go fast,” explains Edward Kearney, CEO of Boundary Layer Technologies. The wings include ailerons that allow the ship to adjust the lift, much like an airplane. But, applying this technology to ocean transport is a new field, which requires the team to design everything from the ground up.

Simplifying R&D Infrastructure to Speed Design Time

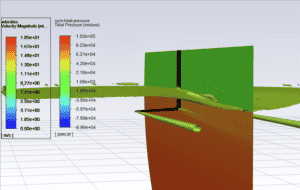

Boundary Layer Technologies faced the challenge of creating a new industry head-on. Cameron Flannery, a Aerospace Engineer at Boundary Layer Technologies, explains, “we have the opportunity to design a new class of vehicle. Something that hasn’t existed before that could potentially revolutionize global trade.” But creating new technology is complex. A major hurdle they faced was creating simulations that would account for free surface – the boundary between air and water – and cavitation effects on wing optimization. Boundary Layer Technologies depended upon Rescale to ensure they had the latest software updates to continue their bleeding-edge research. In this case, the latest release of Ansys included an update that addressed this major design issue. Via the Rescale platform, the team had instant access to this update without any install or configuration.

To create simulations, Boundary Layer Technologies also needed services that could handle the scale of their designs. Flannery explains, “we were creating meshes that took hundreds of gigs of RAM that we could not fit on a local desktop.” Rescale’s platform allowed them to build these meshes remotely. This allowed the small team at Boundary Layer Technologies to create complex designs without requiring the hardware or in-house IT support needed to make it happen. This has given them the resources they need so they can focus on their design. “As a start-up, we have to be lean and agile, and to do that, we use Rescale to maximize our resources and optimize for speed in our design process,” says Kearney.

Leveraging New Designs to Reduce Carbon Emissions

Air cargo accounts for about 2% of global emissions. The growth of a new cargo industry could make an even greater impact on carbon emissions, but only if breakthroughs are made in new products. Rescale removes the complexity of IT infrastructure for organizations to allow them to concentrate on what matters. Access to the latest software and processing power allowed Boundary Layer Technologies to create a design that would have been too computationally complex without this support. Their next step is to concentrate on programmatically optimizing their design using the Rescale platform.