The Case for Seamless and Flexible Simulation Data Governance

Enhancing Product Quality, Compliance, and Collaboration in Simulation-Driven Innovation

In the race to innovate, engineering and scientific teams are using real and synthetic data, machine learning and AI in combination with physics based simulation to generate innovative concepts faster. Yet, product development requires regulatory compliance, attention to the quality of the final product and above all safety for the users.

To strike the balance between speed, quality and safety, companies must enforce a governed approach to ensure reliability of simulations, improve the reproducibility of simulation processes and improve the traceability of simulation data. Which in-turn allows the companies to accelerate the overall product development process and not just concept innovation.

However, any simulation data governance approach needs to accelerate R&D velocity instead of creating obstacles to engineering and scientific computing in order to be successful. Organizations need seamless, flexible governance in-line with the experience of the engineering and scientific users.

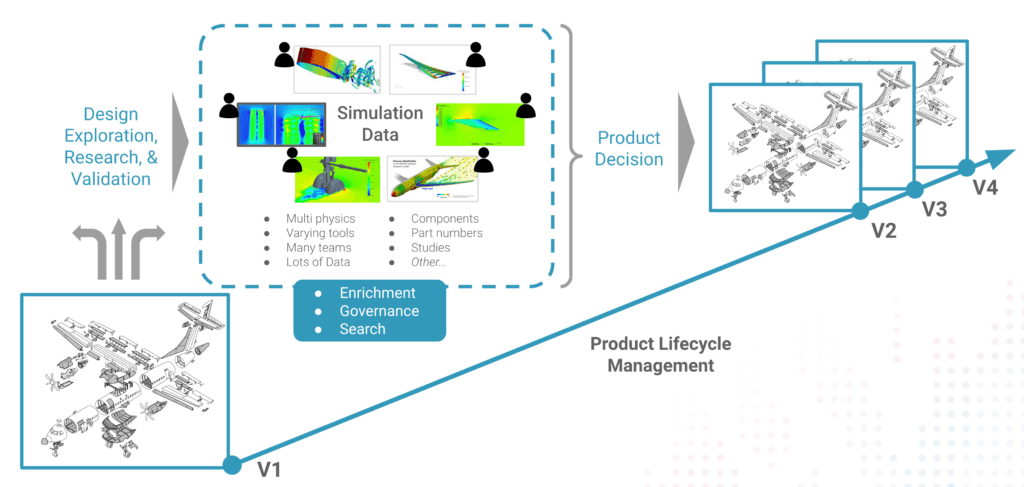

Simulation Data Drives Critical Product Decisions

As an example, consider the development of innovative electric vehicles (EVs). Automotive companies face the complex challenge of evaluating multiple designs and materials, all while navigating critical trade-offs. The vehicle’s structure must not only safeguard its occupants and the battery pack but also be economically viable to produce.

In today’s modern product design process, engineers simulate their ideas, and all tradeoff decisions are made on simulated product performance data. EV engineers must simulate and evaluate characteristics such as occupant and pedestrian safety. Simulation driven innovation mandates adherence to best practices in modeling, ensuring that design decisions are underpinned by reliable simulation outcomes. It’s imperative for companies to comply with and meticulously document relevant standards. For instance, if a vehicle is intended for the European market, adherence to EURO NCAP Protocols is essential and must be clearly documented. Moreover, it is crucial for decision-makers to have timely access to key simulation results. This ensures that informed decisions are not only made but also accurately recorded, aligning with both safety and regulatory requirements.

Simulation Data Has a Unique Complexity

Data Variety and Volume

Simulation data generated through computational models and algorithms, spans a vast array of formats and scales, from simple scalar values to complex multidimensional arrays that represent physical phenomena in engineering, scientific research, and digital twins. The volume of this data has exploded with the advent of more powerful computing resources and the increasing sophistication of simulation software, enabling more detailed and accurate models of real-world systems.

This proliferation of data variety and volume necessitates advanced data management strategies to efficiently store, process, and analyze the information. Effective handling of this diversity and magnitude of data is crucial for extracting meaningful insights that can lead to breakthroughs in product development, optimization of processes, and innovation across industries. Consequently, leveraging cloud technologies and specialized data platforms has become increasingly important, as they provide the scalability and flexibility required to accommodate the exponential growth of simulation data.

Fragmented and Disconnected Data

In simulation-driven design and analysis, data is generated across various stages, from initial design conception through to final validation, involving multiple software tools, simulation environments, and data formats. This diversity inherently leads to fragmented data silos, where critical information is isolated within specific departments, tools, or stages of the product lifecycle, obstructing a unified view of the project and impeding seamless collaboration among teams.

The disconnection between these data silos not only hampers the decision-making process by delaying access to relevant information but also increases the risk of inconsistencies and errors, as the same data may be independently modified or interpreted differently across teams. Moreover, the lack of compatibility among different simulation tools and data management systems exacerbates these challenges, leading to inefficiencies in data transfer, conversion errors, and ultimately, a slowdown in the innovation cycle. Addressing data fragmentation and disconnection requires an integrated data management approach.

Data Security and Sensitivity

Simulation data encompasses a broad spectrum of proprietary and sensitive information, including intellectual property (IP) on product designs, engineering insights, and competitive advantages that are derived from complex computational models and analyses. The security of this data is crucial not only to protect the IP from unauthorized access and potential theft but also to ensure compliance with regulatory standards that govern data privacy and protection in different sectors.

Therefore, robust encryption techniques, secure data storage solutions, and comprehensive access control policies are essential to safeguard simulation data throughout its lifecycle. Furthermore, as simulation increasingly leverages cloud computing for enhanced computational power and storage capabilities, ensuring the security of data in transit and at rest in cloud environments becomes critical. This involves adopting cloud services that adhere to industry-leading security standards and practices, alongside implementing end-to-end encryption and secure data transfer protocols.

The Business Risks of Ungoverned Simulation Data

Inconsistent Simulation Results

The lack of consistency in simulation outcomes can stem from various factors, including unstandardized simulation process methodologies, unstandardized simulation tools, utilization of disparate storage services across teams with lack of transparency for all teams, and the absence of a centralized data management system.

Such inconsistencies erode the confidence of collaborating engineers, scientists and regulators, increasing time-to-market and potentially leading to flawed design choices, and increased product development costs.

Lack of Compliance

In industries where regulatory compliance dictates stringent standards for product safety, performance, and reliability, the governance of simulation data becomes critically important. Ungoverned simulation data can lead to non-compliance issues, where products fail to meet the regulatory standards set by authoritative bodies. This failure can have severe repercussions, including legal penalties, mandatory product recalls, and in severe cases, a complete halt in production, all of which can inflict substantial financial losses and damage to the company’s reputation.

Moreover, in regulated industries such as pharmaceuticals, aerospace, and automotive, compliance isn’t merely a matter of meeting external standards but also involves meticulously documenting the simulation processes and results to demonstrate due diligence. Without a structured approach to managing and governing simulation data, organizations risk producing incomplete, inaccurate, or unverifiable records, thereby failing to prove compliance during audit.

Product Quality Issues

In the context of product development and engineering, simulations are vital for predicting performance, identifying potential design flaws, and optimizing product features especially since organizations are looking for ways to reduce prototyping. However, without rigorous governance of simulation data, there’s a heightened risk of making decisions based on inaccurate, outdated, or inconsistent simulation outcomes. This can lead to design and manufacturing errors not being identified early in the development process, resulting in products that fail to meet the desired quality standards.

Engineering Productivity

The absence of standardized governance of simulation data often results in disorganization which can result in significant time spent on searching for, validating, or recreating existing data, leading to inefficiencies and delays in the development process. This disorganization also increases the likelihood of duplicative efforts across teams, as the lack of a centralized data repository can result in teams unknowingly replicating simulation studies. Furthermore, inconsistencies in simulation results due to ungoverned data can necessitate additional simulations and analyses to correct errors, further impacting productivity.

The siloed nature of ungoverned data also impedes cross-functional collaboration, crucial for innovation and swift market response.

Implementing Simulation Data Governance

Simulation governance involves the establishment of policies and procedures designed to bolster the reliability of predictions made through numerical simulations, thereby fostering confidence and credibility in simulation outcomes. The governance approach should integrate simulation process methods, tools, standards, and data. All supported by a robust data platform and computing infrastructure like a storage fabric.

Simulation data governance is crucial for maintaining the quality of simulation data, and metadata which directly impacts the accessibility, accuracy and reliability of simulation results data used for decision-making. By implementing robust data governance practices, organizations can ensure that simulation data is consistent, traceable, and aligned with compliance standards, thereby minimizing risks associated with lack of compliance, product quality and engineering productivity.

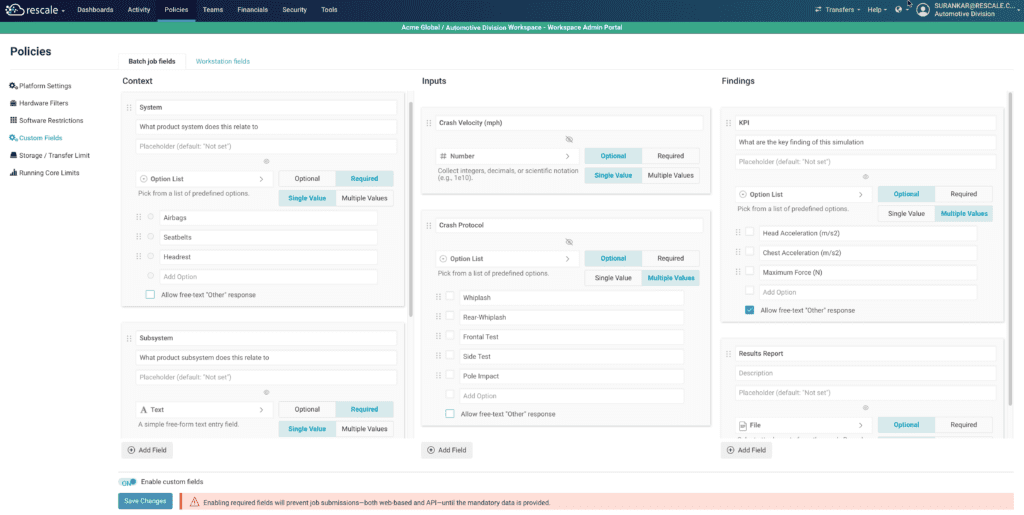

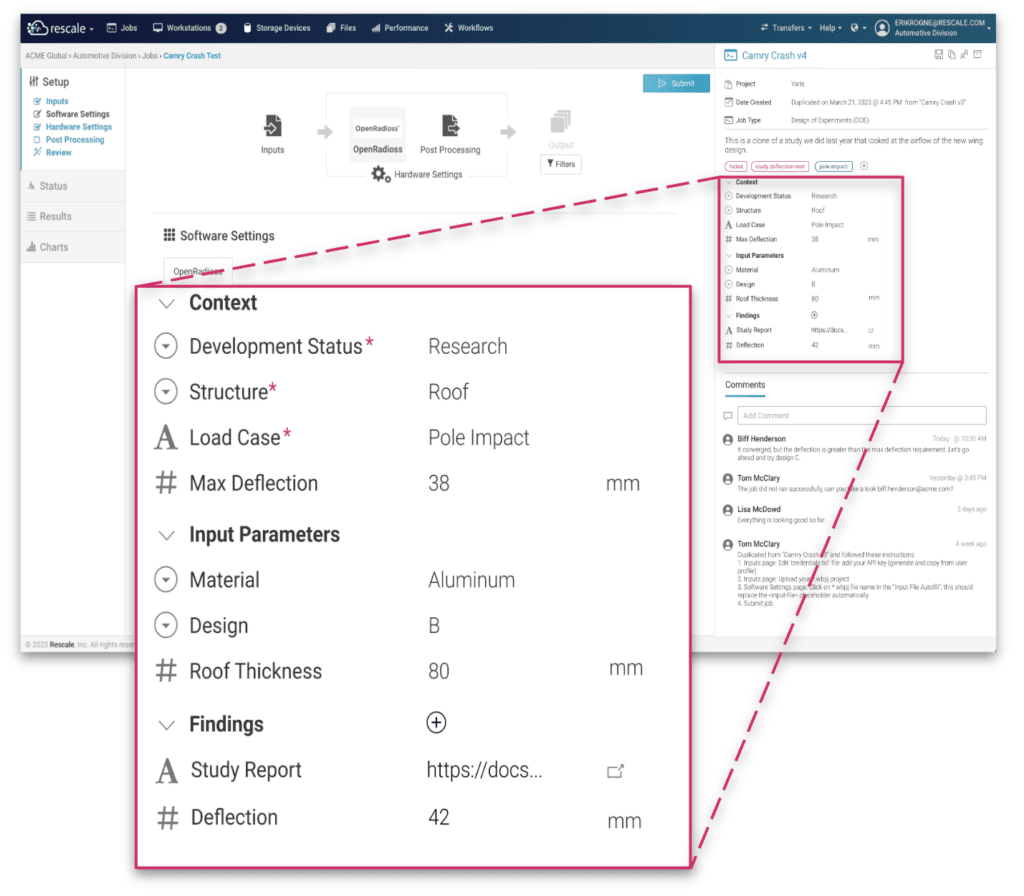

How to Get Started with Simulation Data Governance with Rescale Metadata Management

Product owners, engineering managers and IT managers can deploy custom fields efficiently, for data capture enhancing data quality – visit the metadata management page or contact us to learn more.

Watch the Demo Video on Simulation Data Governance with Rescale Metadata Management