Can Autonomous Driving Make Driving Greener?

What if autonomous driving made it possible for us to conserve energy by drafting like race car drivers? We look into the possibilities.

The advent of autonomous driving presents a transformational shift in transportation and mobility, offering a sophisticated blend of safety, efficiency, and convenience. By harnessing advanced algorithms and sensors, autonomous vehicles hold the potential to significantly reduce accidents attributable to human error, marking a substantial advance in road safety.

The technology’s precision in adhering to traffic laws also contributes to fuel optimization, aligning with broader environmental sustainability goals. Beyond these tangible benefits, autonomous driving promises to redefine the passenger experience, turning travel time into an opportunity for productivity or relaxation.

But there’s an additional benefit autonomous driving might be able to provide. With multiple autonomous vehicles working in coordination, these vehicles can reduce wind drag by drafting off of each other, helping lower their collective energy consumption.

But How? With a little bit of help from physics and simulation.

The Physics of Drafting

When two or more vehicles align front to rear, they can achieve higher velocity than a solitary vehicle. This synergy is created by the low-pressure wake behind the leading car, which diminishes the aerodynamic resistance on the following car as it gets close behind the leading car.

As this occurs, the trailing vehicle pushes a current of high-pressure air ahead, ensuring that less fast-moving air reaches the lead car’s spoiler. The cumulative effect is a reduction in drag for both vehicles, an aerodynamic efficiency that translates to less force for the motor to overcome, providing the possibility for greater speeds or more fuel efficiency.

If you are a NASCAR fan, this is entirely old news. In 1960, behind the wheel of a Chevrolet that lagged in raw speed, drafting allowed Junior Johnson to leverage the aerodynamics of the leading vehicles to overcome his speed deficit, clinching an improbable victory at Daytona 500. Johnson’s peers soon adopted this practice, discovering that a line of drafters could achieve higher speeds and increase fuel efficiency, minimizing the need for pit stops.

In cycling, riders strategically form pelotons during races such as the Tour de France. Those leading the pack face the most significant wind resistance, offering those behind an aerodynamic advantage due to the reduced drag. Similarly, in speed skating, athletes position themselves closely behind one another, capitalizing on the leader’s aerodynamic wake to conserve energy for pivotal moments in the race.

But what about us non-professional NASCAR and Tour de France athletes? Can the average driver benefit from this phenomenon if it can be done safely through autonomous vehicles?

Does Drafting Work for Everyday Drivers?

In a compelling experiment on the television show “MythBusters,” drafting potential was explored using an 18-wheeler truck. They found that maintaining a distance of 100 feet behind the truck bolstered fuel efficiency by an impressive 11 percent.

This efficiency leaped to 39 percent when the trailing distance was reduced to a mere 10 feet.

However, they noted that in real-life hypermiling, the drivers were likely to brake and accelerate more often, diminishing their efficiency gains.

Drafters will always face the constant threat of abrupt stops by the vehicle in front. Failure to react might lead to severe accidents.

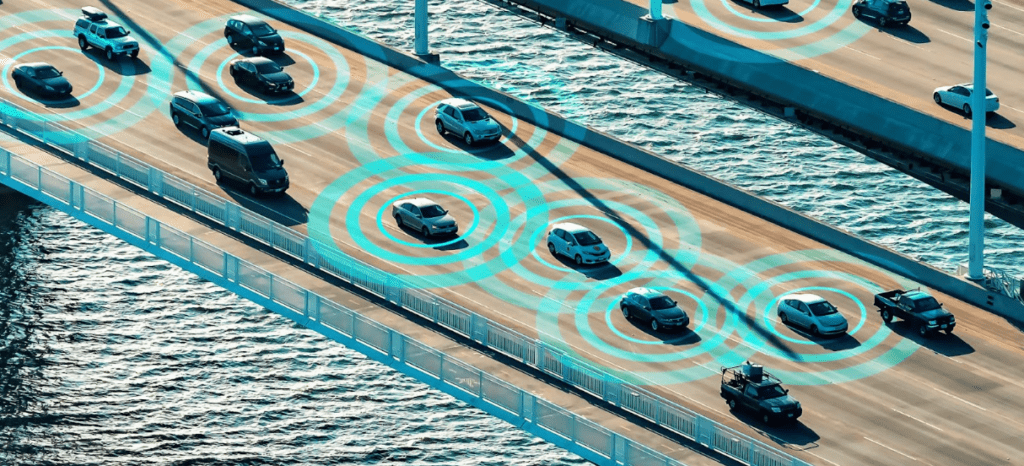

Enter Autonomous Fleets

Autonomous fleets refer to a collection of self-driving vehicles that are coordinated and operated without human intervention, using advanced technologies such as artificial intelligence, machine learning, sensors, and GPS. For example, Cruise is rolling out its autonomous fleet in several US cities this year.

Consider the potential transformation of ride-sharing platforms like Uber, where passengers may soon seek to “draft” with others, aligning their travel not just by destination but by precise coordination of speed and route.

This phenomenon extends to a broader urban context, where the traditional concept of high-occupancy vehicle (HOV) lanes could evolve into intelligent corridors. In these spaces, clusters of autonomous high-occupancy vehicles would function as unified entities, braking and accelerating as one.

This seamless interaction promises increased efficiency and safety and a paradigm shift in our collective approach to mobility, underscoring the profound impact of technology on societal behavior and infrastructure planning.

But where do automotive engineers even begin to evaluate the feasibility of drafting for the average sedan if it were made autonomous? They can begin with physics simulations.

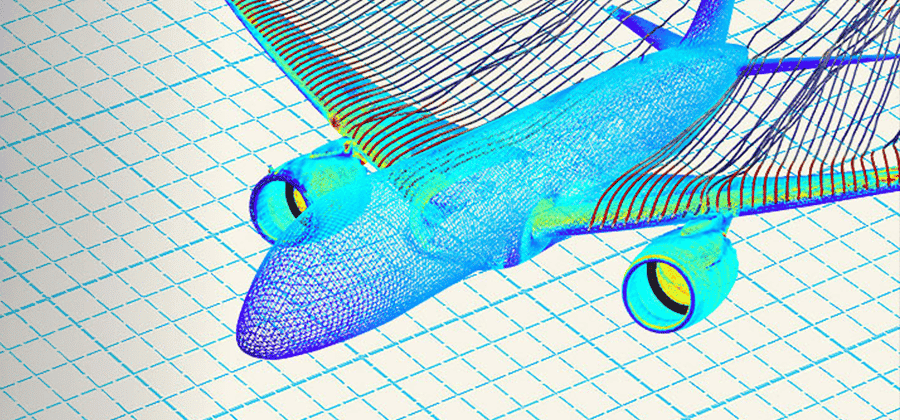

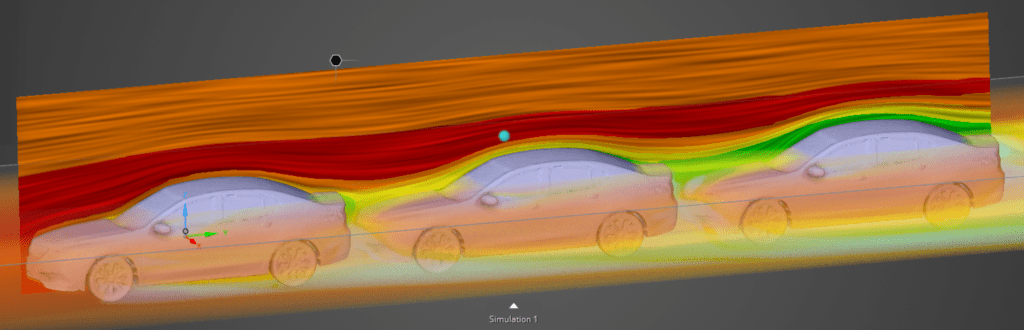

Airflow over a solitary car simulated in Ansys Discovery Live on a Rescale Elastic Cloud Workstation.

Simulating Early Concepts

Early conceptual simulation represents a critical step in modern automotive design, development, and testing. By applying simulation at the inception of a project, organizations can illuminate potential design weaknesses and mitigate them before they manifest in physical prototypes.

The cost-savings are tangible, with the big promise of reducing the reliance on physical testing to not only speed innovation but to also ensure greater safety. More profound, however, is the effect on creativity and collaboration.

Early concept simulation catalyzes idea iteration, allowing multidisciplinary teams to explore alternative designs and foster a shared vision. The cumulative effect of these benefits transforms early concept simulation from a mere procedural step into a strategic lever that minimizes risk, enhances the product’s robustness, and empowers organizations to navigate the turbulent seas of modern product development with precision and agility.

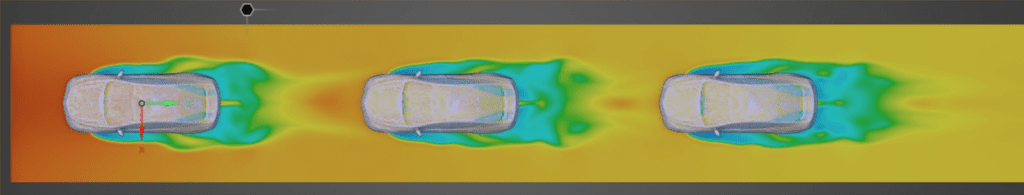

To illustrate the value of early conceptual simulations, I constructed a computational fluid dynamics (CFD) model of my 2015 Acura TLX. I positioned this model within a virtual wind tunnel, replicating the dynamics at a speed of 65 miles per hour.

I then sought to answer the question: What is the optimal distance between a leading car and a trailing car to maximize the aerodynamic advantage of drafting?

The data visualizations from our simulations are filtered to display only the regions of reduced air pressure, represented by spherical markers. The intensity of the pressure is depicted through a color gradient, where the blue spheres signify regions of the lowest pressure.

Visualization of the low-pressure area behind a solitary car. Prepared in Ansys Discovery Live on a Rescle Elastic Cloud Workstation.

The physics simulation shows that the highest gains will be had when the cars are packed tightly together, within inches of one another. In this scenario, the lead car’s efficiency improves by 11 percent. The middle car gains 35 percent, and the trailing car gains 37.5 percent, as compared to the solitary car.

Obviously, engineers (and drivers) would want to build in some factor of safety. Should it be one car length? Two car lengths? What’s the trade-off? When separated by a one-car distance, these gains slip substantially. The lead car gains only 0.5%, the middle car gains 2%, and the trailing car gains 2.2%. The cars cannot fully exploit each other’s slipstreams at this separation.

An autonomous driving system maintaining a full car-length separation might fail to entice the average driver. Without significant advances in autonomous driving technology, drafting seems to be a difficult tactic for saving energy.

Such preliminary insights like these, while seemingly straightforward, underscore a profound strategic implication: the earlier the recalibration of a faulty design concept, the better.

Redirecting design trajectories late in the game can greatly hurt product production goals. By harnessing the precision of early-stage physics simulations and meticulously iterating through potential use cases, engineers can sidestep these eleventh-hour pitfalls, ensuring they come up with product improvements quickly and efficiently.

AI Engineering on the Rescale Platform

Rescale makes physics simulation easily accessible to engineering companies by offering on-demand licensing for many best-in-class simulation software. Rescale is secure and built for HPC environments. It also offers ways to run open-source physics and SciML simulation software and custom code written in Python, Julia, or even Fortran. This is where the magic happens.

Engineers can use newer machine-learning (ML) techniques to explore a broad scope of design options so engineers can do trade-off analyses in real-time.

For example, it would be possible to build an AI/ML model that learns the pressure profiles of the leading and trailing cars for every combination of separation distance. Once learned, engineers can ask the AI/Ml model any what-if questions they like and get instantaneous visual feedback!

In the future, it would be possible to pipe the AI/ML model into an ADAS simulation for real-time physics-informed autonomous driving. With access to a complete ecosystem of simulation tools, Rescale offers engineers the perfect sandbox for developing such cutting-edge simulations.

Examples and Tutorials on Rescale

Several examples and tutorials are available to try on Rescale with our free trial.

To explore external aerodynamics on Ansys Discovery Live on Rescale, take a look at the video at the bottom of our Elastic Workstations overview page. Try the examples that ship with the Discovery Live product.